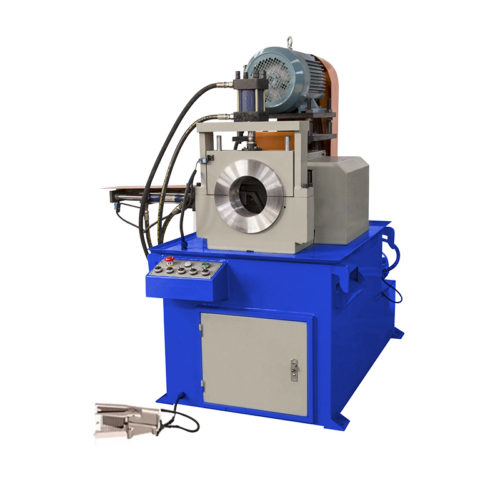

- Hand feeding, automatic blade driving and retracting, high speed, doubles the production capacity.

- Fits end-face interior and external angles of pipes and bars, finishes the riveting and coping in a single time with high efficiency and accuracy.

- Align the center-line between the processing piece and saw plate, the clamping die and saw plate are precisely designed and finish the processing evenly every single time.

- The saw plate is specially designed, saw blade standardized, the adjustment of blade is easy and quick.

- All machines need to be engineered and customized, lead-time is 3 to 4 weeks.

-

Sale!

-

Sale!

What our Pipe Beveling and Chamfering Machines will bring to you:

- High efficiency: Cycle normally in the 3-10 second range

- Safety: No more hand-grinding or torching of weld bevels, safer than handgrinding

- Automated pipe beveling machines are many times faster than portable units

- Accurately machines weld bevel and faces pipe square

- Sturdy construction and quality materials for years of dependable service

- Pipe beveling machines have low operating costs and virtually no maintenance

- Machines available for ½" up to 20" OD pipe or tubing, ODM/OEM/Customization service is offered

- Adjustable cutter head quickly set with gauges

- Uses standard off-the-shelf carbide inserts. Tooling is available for custom angles and J-bevels

- Interchangeable grips for different size pipe or tubing

- Electronic variable-speed drive

- Heavy-duty spindle that rides on machine tool-type linear ball rails

- Totally enclosed cutting area to protect the operator with optional dome shield

- All machines need to be engineered and customized, lead-time is 3 to 4 weeks.

-

Sale!

What our Pipe Beveling and Chamfering Machines will bring to you:

- High efficiency: Cycle normally in the 3-10 second range

- Safety: No more hand-grinding or torching of weld bevels, safer than handgrinding

- Automated pipe beveling machines are many times faster than portable units

- Accurately machines weld bevel and faces pipe square

- Sturdy construction and quality materials for years of dependable service

- Pipe beveling machines have low operating costs and virtually no maintenance

- Machines available for ½" up to 20" OD pipe or tubing, ODM/OEM/Customization service is offered

- Adjustable cutter head quickly set with gauges

- Uses standard off-the-shelf carbide inserts. Tooling is available for custom angles and J-bevels

- Interchangeable grips for different size pipe or tubing

- Electronic variable-speed drive

- Heavy-duty spindle that rides on machine tool-type linear ball rails

- Totally enclosed cutting area to protect the operator with optional dome shield

- All machines need to be engineered and customized, lead-time is 3 to 4 weeks.

-

Sale!

What our Pipe Beveling and Chamfering Machines will bring to you:

- High efficiency: Cycle normally in the 3-10 second range

- Safety: No more hand-grinding or torching of weld bevels, safer than handgrinding

- Automated pipe beveling machines are many times faster than portable units

- Accurately machines weld bevel and faces pipe square

- Sturdy construction and quality materials for years of dependable service

- Pipe beveling machines have low operating costs and virtually no maintenance

- Machines available for ½" up to 20" OD pipe or tubing, ODM/OEM/Customization service is offered

- Adjustable cutter head quickly set with gauges

- Uses standard off-the-shelf carbide inserts. Tooling is available for custom angles and J-bevels

- Interchangeable grips for different size pipe or tubing

- Electronic variable-speed drive

- Heavy-duty spindle that rides on machine tool-type linear ball rails

- Totally enclosed cutting area to protect the operator with optional dome shield

- All machines need to be engineered and customized, lead-time is 3 to 4 weeks.

-

Sale!

- Hand feeding, automatic blade driving and retracting, high speed, doubles the production capacity.

- Fits end-face interior and external angles of pipes and bars, finishes the riveting and coping in a single time with high efficiency and accuracy.

- Align the center-line between the processing piece and saw plate, the clamping die and saw plate are precisely designed and finish the processing evenly every single time.

- The saw plate is specially designed, saw blade standardized, the adjustment of blade is easy and quick.

- All machines need to be engineered and customized, your name and private labels are welcome. Lead-time is 3 to 4 weeks.

-

Sale!

- Hand feeding, automatic blade driving and retracting, high speed, doubles the production capacity.

- Fits end-face interior and external angles of pipes and bars, finishes the riveting and coping in a single time with high efficiency and accuracy.

- Align the center-line between the processing piece and saw plate, the clamping die and saw plate are precisely designed and finish the processing evenly every single time.

- The saw plate is specially designed, saw blade standardized, the adjustment of blade is easy and quick.

- All machines need to be engineered and customized, your private label and design are welcome. Lead-time is 3 to 4 weeks.